The fuel pump eccentric and the oil slinger are NOT the same thing so get that idea out of your head; what you may have done is either totally missed the eccentric with the lever on the fuel pump (so it's in front of the eccentric) or you've gotten the lever under the eccentric.

If the pump went in super easy and you feel didn't much resistance the above is very likely!

Mike

TOA # 70

1966 won't start- thinking fuel pump

-

Graniteman

- Posts: 48

- Joined: Sat Aug 15, 2009 9:00 am

- TOA Membership Number: 70

- Years Owned: Owned a '69 back in about '77, this cat was a legend in the Nebraska panhandle, it was very fast even for it's size. It would absoloutly fog the front tires from a standing start; I don't mean spin them, I mean just boil 'em from a standing start for at least 100' (measured)! I know what you're thinking, they weren't old rag tires they were modern Yokohoma radials. I'm sure this car would have ran 150mph too because many times I had the cruise set on 135 with 1/2 the gas pedal left. BTW this was in the middle of nowhere Wyoming.

I'm finally about to start work on my '66 that I've owned for 10 years. I plan to make sure my '66 425 runs just as strong as my '69 455 did. I hope to be doing some write-ups for the Driver as I go through the '66. I'll be updating it with disc brakes, electric fans (gasp), good stereo system, battery in the trunk etc., etc. as time and money allows.

I also may be building some new wheels with the correct offset, etc. - Location: Hastings, Nebraska

-

Mikel

- Posts: 136

- Joined: Tue Aug 11, 2009 7:26 am

- TOA Membership Number: 100

- Location: New Haven, CT

Re: 1966 won't start- thinking fuel pump

Looking at mine, looks like a mixture of 1/4NPT (Hidden in the photo) and flared fittings. Yes, tape will help seal the NPT fittings.

One easy thing you can do to confirm that your problem is lack of fuel is to fill the carburetor's bowl with gasoline via the vent. Engine should run for a few seconds.

One easy thing you can do to confirm that your problem is lack of fuel is to fill the carburetor's bowl with gasoline via the vent. Engine should run for a few seconds.

-

silverflash

- Posts: 16

- Joined: Thu Aug 29, 2013 5:24 pm

- TOA Membership Number: 0

- Years Owned: 1966

Re: 1966 won't start- thinking fuel pump

Mikel wrote:Looking at mine, looks like a mixture of 1/4NPT (Hidden in the photo) and flared fittings. Yes, tape will help seal the NPT fittings.

One easy thing you can do to confirm that your problem is lack of fuel is to fill the carburetor's bowl with gasoline via the vent. Engine should run for a few seconds.

my leak is at that block looking thing where the fitting screws into it from the top. It is very slight. I got some teflon paste and will try that tonight. so that's a flare fitting? supposedly you don't need teflon tape for them, so what does that mean if it is a flair fitting and it is leaking? what is that saucer thing attached to it right there? If i need to replace that, would like to know what it's called and so far nothing is coming up.

the pump went in with having to push against it as we put the nut on the top stud and the bottom bolt so i am pretty sure the pump is in right. right now, just worried about the link...

-

Mikel

- Posts: 136

- Joined: Tue Aug 11, 2009 7:26 am

- TOA Membership Number: 100

- Location: New Haven, CT

Re: 1966 won't start- thinking fuel pump

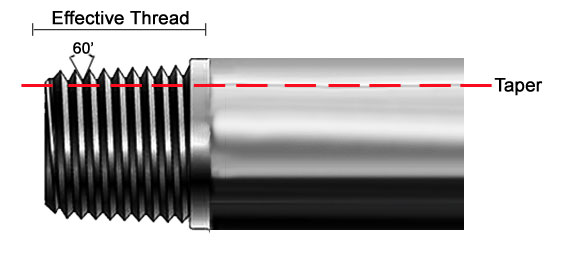

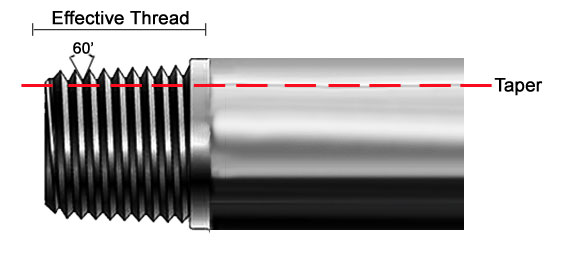

Quick rule of thumb: If threads are tapered, it's the theads that seal and can benefit from teflon tape. If the threads are straight, the threads aren't doing the sealing and tape won't help at all, as the sealing is being done somewhere else. Also, I think you will have better luck with tape than paste.

An example of flared fitting:

Pipe thread (tapered):

Besides the leaking, is your engine running now? Sounds like gasoline is getting pumped to the carburetor...

An example of flared fitting:

Pipe thread (tapered):

Besides the leaking, is your engine running now? Sounds like gasoline is getting pumped to the carburetor...

Re: 1966 won't start- thinking fuel pump

silverflash wrote:my leak is at that block looking thing where the fitting screws into it from the top. It is very slight. I got some teflon paste and will try that tonight. so that's a flare fitting? supposedly you don't need teflon tape for them, so what does that mean if it is a flair fitting?

Steel flare on a brass fitting = brass gets distorted when over-tightened. Steel flare may or may not also be distorted. You have three choices:

1. Tighten it some more, pray that the leak seals.

2. Replace the brass block with one that isn't distorted. Hope that the steel flare isn't distorted now, too.

3. Seal the flare with dead-soft copper "flare washers". I have heard of these, but never seen or used them. Supposedly they're an ultra-soft copper washer that's been stamped to fit the 45 degree flare.

silverflash wrote: what is that saucer thing attached to it right there? If i need to replace that, would like to know what it's called and so far nothing is coming up.

Good luck getting a replacement pulse damper. These were perhaps used in conjunction with the "balanced pressure" needle-and-seat arrangement of the early Q-jet carbs. (The ones that were recalled due to fire hazard.)

silverflash wrote:the pump went in with having to push against it as we put the nut on the top stud and the bottom bolt so i am pretty sure the pump is in right. right now, jsut worried about the link...

Doesn't sound good to me. I'd expect the arm to push the pump body away from the block, so that the nuts have to compress the spring before the pump will sit flush.

Fuel pump testing--fill the float bowl of the carb with gasoline so the engine will run awhile.

Pressure--connect a fuel pump pressure gauge to the pump outlet (damper outlet is fine in this case) Pressure should be about 6 psi. Not less than 4 psi. Not more than 8 psi.

Volume--connect a hose so that fuel can be routed to a coffee-can or bucket or similar. Run engine for 15 seconds. Measure fuel output.

Vacuum--connect vacuum gauge to fuel pump INLET. Run engine. Pump should develop vacuum. When engine stalls, pump should HOLD vacuum for >30 seconds.

-

silverflash

- Posts: 16

- Joined: Thu Aug 29, 2013 5:24 pm

- TOA Membership Number: 0

- Years Owned: 1966

Re: 1966 won't start- thinking fuel pump

Schurkey wrote:silverflash wrote:my leak is at that block looking thing where the fitting screws into it from the top. It is very slight. I got some teflon paste and will try that tonight. so that's a flare fitting? supposedly you don't need teflon tape for them, so what does that mean if it is a flair fitting?

Steel flare on a brass fitting = brass gets distorted when over-tightened. Steel flare may or may not also be distorted. You have three choices:

1. Tighten it some more, pray that the leak seals.

2. Replace the brass block with one that isn't distorted. Hope that the steel flare isn't distorted now, too.

3. Seal the flare with dead-soft copper "flare washers". I have heard of these, but never seen or used them. Supposedly they're an ultra-soft copper washer that's been stamped to fit the 45 degree flare.silverflash wrote: what is that saucer thing attached to it right there? If i need to replace that, would like to know what it's called and so far nothing is coming up.

Good luck getting a replacement pulse damper. These were perhaps used in conjunction with the "balanced pressure" needle-and-seat arrangement of the early Q-jet carbs. (The ones that were recalled due to fire hazard.)silverflash wrote:the pump went in with having to push against it as we put the nut on the top stud and the bottom bolt so i am pretty sure the pump is in right. right now, jsut worried about the link...

Doesn't sound good to me. I'd expect the arm to push the pump body away from the block, so that the nuts have to compress the spring before the pump will sit flush.

Fuel pump testing--fill the float bowl of the carb with gasoline so the engine will run awhile.

Pressure--connect a fuel pump pressure gauge to the pump outlet (damper outlet is fine in this case) Pressure should be about 6 psi. Not less than 4 psi. Not more than 8 psi.

Volume--connect a hose so that fuel can be routed to a coffee-can or bucket or similar. Run engine for 15 seconds. Measure fuel output.

Vacuum--connect vacuum gauge to fuel pump INLET. Run engine. Pump should develop vacuum. When engine stalls, pump should HOLD vacuum for >30 seconds.

based on what you said, the pump sounds like it is in right... and it looks like i should have a flare fitting afterall. i just didn't know the terminology. I will pull off and see if it's flared, meaning the pipe. Could you have a npt and a flared pipe or is that stupid? sorry for the silly questions but i really don't know. If it is a flared fitting, perhaps all i need to do is tighten a wee bit more then. what came standard on these engines in the toro? flared right there where it goes into fuel pump from carb?

Re: 1966 won't start- thinking fuel pump

There is a difference between TUBING and PIPE.

Tubing is measured by the OUTSIDE diameter.

Pipe is measured by the INSIDE diameter.

Tubing (in a plumbing application) is almost never secured by threads cut into the wall of the tube. Tubing might be secured/sealed by flares or by compression ferrules. Flares are considered more reliable.

Pipe (in a plumbing application) is almost always secured by tapered threads cut into the wall of the pipe. Thread distortion results in metal-to-metal contact, which seals the threads. (but pipe sealing compound makes it seal better, and makes it easier to disassemble later.)

The tube and tube nut attached to the brass block in the photo are guaranteed to be a flare fitting. The block will be machined for an inverse flare, the tubing will be a 45 degree double-flare. I may have to go to the garage and snap a photo or two.

Some tubing and fittings have 37 degree flares. This goes back to aircraft and other high-performance use--but was never used by GM on ordinary passenger cars.

Tubing is measured by the OUTSIDE diameter.

Pipe is measured by the INSIDE diameter.

Tubing (in a plumbing application) is almost never secured by threads cut into the wall of the tube. Tubing might be secured/sealed by flares or by compression ferrules. Flares are considered more reliable.

Pipe (in a plumbing application) is almost always secured by tapered threads cut into the wall of the pipe. Thread distortion results in metal-to-metal contact, which seals the threads. (but pipe sealing compound makes it seal better, and makes it easier to disassemble later.)

The tube and tube nut attached to the brass block in the photo are guaranteed to be a flare fitting. The block will be machined for an inverse flare, the tubing will be a 45 degree double-flare. I may have to go to the garage and snap a photo or two.

Some tubing and fittings have 37 degree flares. This goes back to aircraft and other high-performance use--but was never used by GM on ordinary passenger cars.

-

silverflash

- Posts: 16

- Joined: Thu Aug 29, 2013 5:24 pm

- TOA Membership Number: 0

- Years Owned: 1966

Re: 1966 won't start- thinking fuel pump

ok, i will remove the fitting, check the flare, clean the threads, put a little dab of teflon paste on the threads and retighten. I won't go crazy on the paste.

it can't hurt if i just give it a little paste on the threads?

it can't hurt if i just give it a little paste on the threads?

Re: 1966 won't start- thinking fuel pump

The threads don't seal anything. They do nothing but apply pressure to the flare. Teflon paste or tape on the threads is a total waste of effort.

Having said that, I have been known to put a dab of Teflon paste on the back side of the flare where the nut presses against it (NEVER on the "front" side!) and it did help seal an otherwise problematical fuel fitting. Not a recommended procedure.

FIRST you should try tightening it up a touch.

Having said that, I have been known to put a dab of Teflon paste on the back side of the flare where the nut presses against it (NEVER on the "front" side!) and it did help seal an otherwise problematical fuel fitting. Not a recommended procedure.

FIRST you should try tightening it up a touch.

-

silverflash

- Posts: 16

- Joined: Thu Aug 29, 2013 5:24 pm

- TOA Membership Number: 0

- Years Owned: 1966

Re: 1966 won't start- thinking fuel pump

So I tightened the fitting down some more. Cranked engine and it fired up and stayed up but was leaking more than before but from the area between the center of the threaded male fitting and the tubing. Darn. So am going to replace the tubing and the nut side of the connection. Should I replace the square piece? What's the chance of that being ok and just the flare on the tubing being munged? If I do have to replace the square bit I am fearful I will mess up the connection going to the saucer thing then be sol. Ideas?

Who is online

Users browsing this forum: No registered users and 7 guests